From fork to facility

Discover how enzymes can help increase solubility from food waste for more efficient use in biogas facilities.

Boost capacity for higher biogas yields

From gate fees to disposal costs, our solutions add value right through the food waste-to-biogas conversion process. If your plant is constrained by capacity, enzymes can help. They make your feedstock more soluble so you can maintain low viscosity while increasing organic content.

That means a higher concentration of organic content flowing into your digester. The end result is higher biogas yields for your plant. With higher concentrations of waste moving through your plant, you can also boost your gate fees.

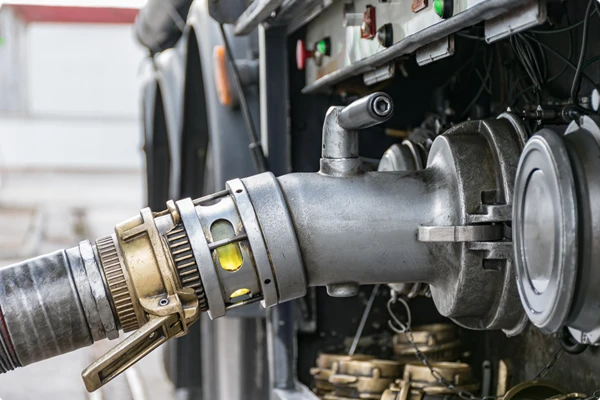

Enzymatic pretreatment of food waste

Enzymes work as biocatalysts for biological processes, and can help the production of biogas become more cost-effective and sustainable in a number of ways.

In this lab video, we demonstrate how enzymatic pretreatment of food waste for biogas production can result in several benefits, including lower viscosity, better separation, and higher dry matter going into the digester.

Lower reject matter disposal costs

The depackaging process can leave behind significant amounts of organic material. This reject matter represents lost biogas revenue for your plant. It also leads to higher disposal fees. The depackaging process is more effective when organic matter is solubilized. Our solutions improve solubility and can thereby improve the separation. That means less organic material left behind in the reject stream and less volumes to dispose of. The result for your plant is more organic material fed to the digester and lower disposal costs.

Lower digestate disposal costs with the same biogas yields

Disposing of digestate can lead to high costs for your plant. To reduce your disposal costs, you can reduce the volume of feed through your digester while maintaining organic concentration and biogas yields.

That’s because our solutions reduce viscosity. Even with less liquid in your feed, it’s still manageable for your process.

Want to explore our enzymatic solution for biogas from agriculture & industry?

What could this mean for your business?

Fill in the form below and we’ll be in touch.

One more step…

To complete the get in touch form or sign up, please click on the button below to enable cookies.