Renewable diesel pretreatment

Better yields. Higher quality. Less waste.

Meet HVO/HEFA specifications while reducing bleaching clay dosage and oil loss

Quara® LowP optimizes yield and processes

Do you run a crushing plant or pretreatment process? Then Quara® LowP will help you meet HVO/HEFA quality specifications with maximum yield and minimum by-products. It’s also proven to provide process efficiencies across diverse vegetable oil feedstocks, including blends with tallow, used cooking oil and distillers' corn oil.

Explore solutions to meet your plant’s needs

Discover how Quara® LowP helps you meet quality specifications with maximum yield, feedstock flexibility, and less waste.

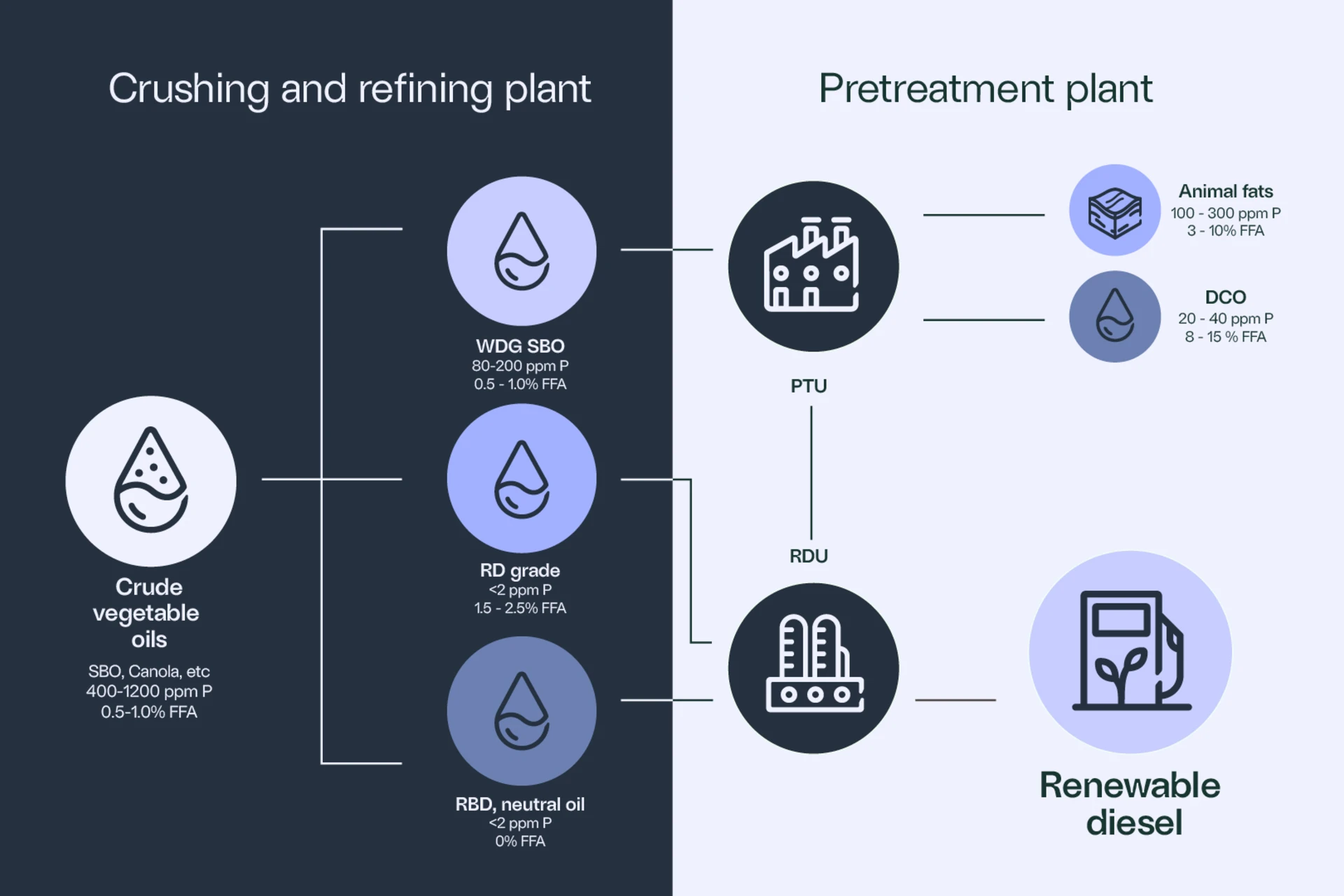

Crushing and refining plant

Don’t over-refine vegetable oils at the expense of lower yields.

Pretreatment plant

Don’t hide your pretreatment inefficiencies behind excessive amounts of bleaching clay and water.

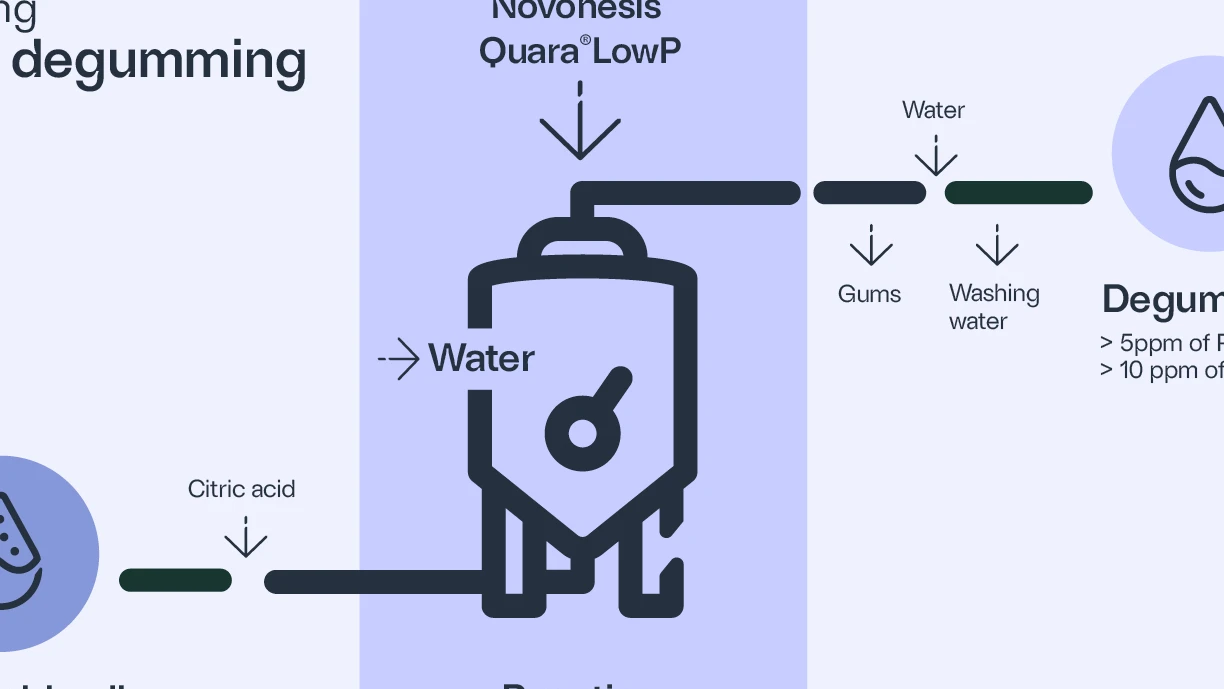

Quara® LowP — a low-CAPEX, drop-in solution

If you haven’t yet explored the benefits of enzymes in your pretreatment unit, now’s the time to get more out of your acid degumming line. This new process allows you to add Quara® LowP directly to your existing reaction tank with no changes required to your plant.

Contact us today to learn more.

What could biosolutions mean for you?

Interested to know what biosolutions could do for your renewable diesel plant? Then fill out the form and one of our experts will be in touch soon.

One more step…

To complete the get in touch form or sign up, please click on the button below to enable cookies.