Overcoming changes in raw material quality

Case study: Learn how a brewer improved both production efficiency and quality of beer despite a change in raw material quality.

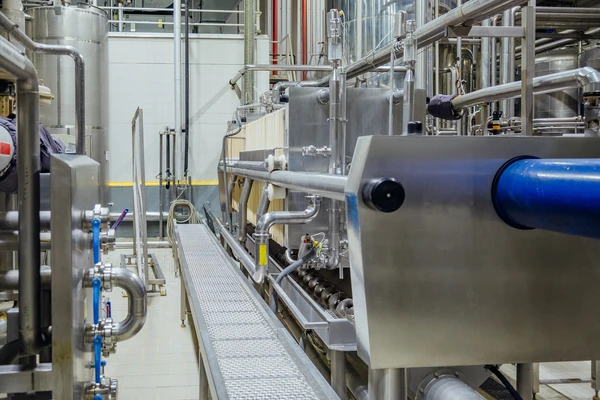

Barley ban impacted brewer’s efficiency and quality

A country-wide ban on barley imports caused significant variation in raw material quality, impacting production efficiency and the quality of finished beer for an international brewer.

Higher production efficiency with enzymes

A range of standard and customized Novonesis solutions, including Shearzyme® 500 L (filtration), Neutrase® 0.8 L BrewQ and Termamyl® SC 4X, helped the brewer optimize its filtration process and cope with fluctuations in raw material quality. This improved total production efficiency and the quality of the finished beer.

Location: Asia-Pacific

Explore more success stories.

Solving a logistical challenge

Using SmartBev™ frozen liquid yeast (FLY) let this brewer produce beers closer to market, reducing logistical costs and complexity.

Troubleshooting a process bottleneck

Challenge: Something was making a regional brewer’s lautering process take much longer. And the brewer couldn’t produce the amount of beer required due to the longer brewing cycle time.

Enzymes help overcome equipment limitation

Challenge: An international brewer wanted to implement a known recipe into another of its breweries. But the “new” brewery did not have a cereal cooker. How to overcome the equipment limitation?