Degumming

Achieve more yield with our degumming solutions

Enzymatic degumming improves gum separation and reduces oil losses- give you more yield, more valuable end-products and less waste

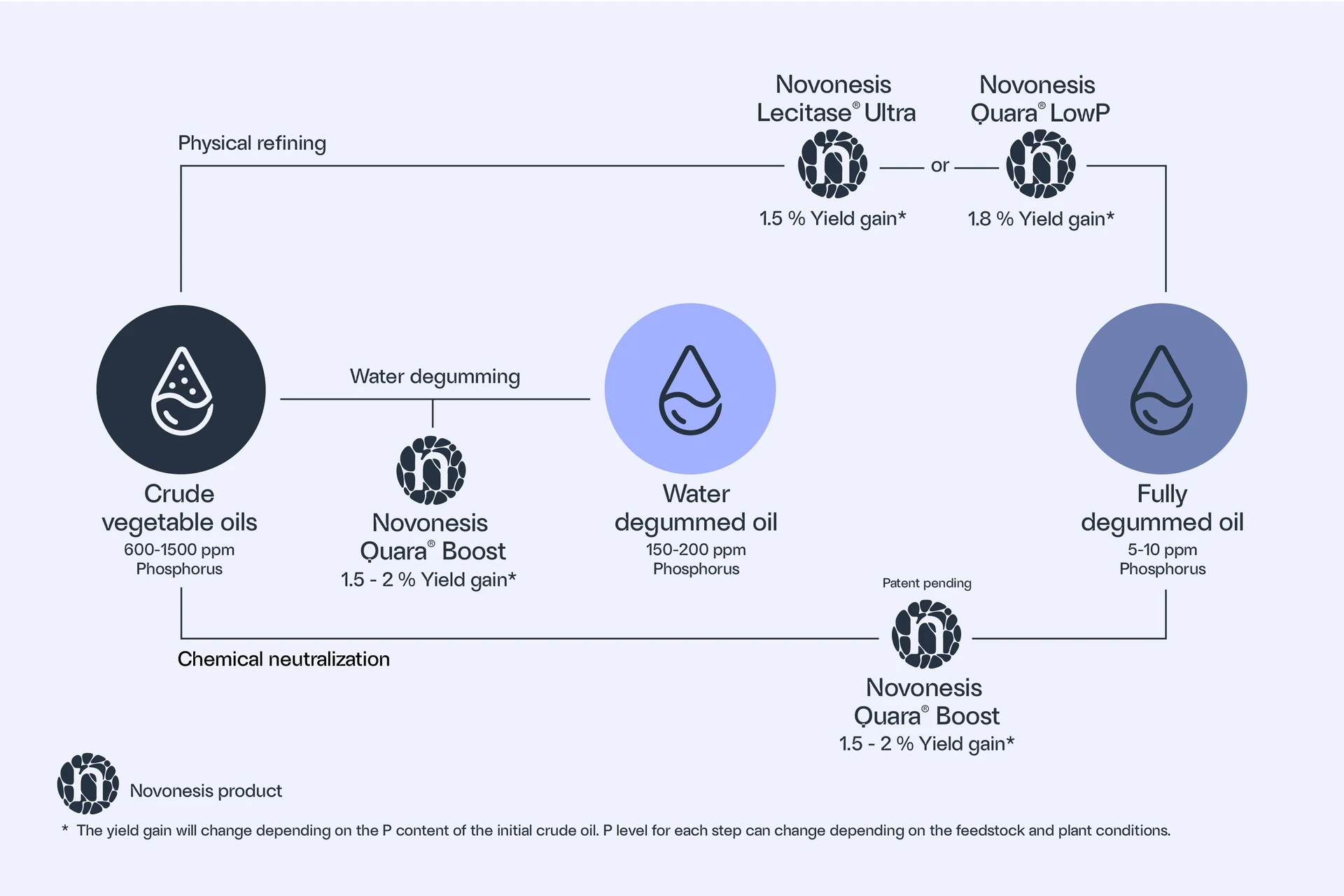

Our complete portfolio for different refining routes and needs

- Soybean Oil

- Rapeseed Oil

- Sunflower Oil

- Rice Bran Oil

- Corn Oils

- All other oils and blends that demand phosphorus reduction for food, biodiesel or renewable diesel application

If you haven’t considered optimizing your process through the addition of enzymatic technology, you’re almost certainly leaving money on the table.

By adding our enzymes to your refining process, you can convert more phospholipids to oil. That means cutting out by-products and boosting oil yields by up to 2%.

Try our oil profit calculator to evaluate the main steps of your refining process and find the combination that will maximize gains and minimize loss for your plant.

Our Degumming Excellence Centre in Brazil provides customers with unprecedented access to the latest technology and expertise in the industry.

From a state-of-the-art laboratory – complete with a pilot plant for the small-scale testing of industrial-scale solutions – to dedicated space for training and meetings, the Degumming Excellence Centre puts a wealth of Novonesis’ refining resources and expertise at your disposal, all under one roof.

Want to learn more?

See how enzymatic degumming can work for you

Getting the most out of enzymatic solutions

Enzymatic degumming is a relatively new process that demands a complete understanding of the plant to optimize gains. That’s why we developed a proven business model. In Brazil, we have partnered with industrial tech company BR Process to ensure our customers get the most from their enzymatic solutions.

Improving alkaline refining efficiency

Whether you’re new to enzymatic refining or simply want to better understand the process and science behind it, this free, on-demand webinar gives you the complete picture.

Along with an introduction to the use of enzymes in oil refining, including how that process compares to traditional alkaline refining, you’ll also hear how the innovative enzymatic technology in Quara® Boost helps producers improve their yield.

Exceptional collaboration, exceptional results

Finding the appropriate processing technology that is both economically viable and environmentally sustainable can be a challenge. Hear from BR Process, an industry technology partner of Novonesis that work with clients in oils and fats processing and refining. In this video, they share about top concerns of customers and how enzymatic solutions create additional value of up to $20/ton.

Recover the extra oil hidden in plain sight

Quara® Boost is an enzymatic solution that helps you recover the oil that’s hiding in plain sight – while also reducing unwanted by-product without increasing the acidity of the oil.

Want expert advice on your opportunities and degumming challenges?

We’re happy to put you in touch with our refining experts who will provide you expert advice and a free sample. Our refining experts can help you:

- Improve production capacity and output

- Increase yields and process consistency

- Provide guidance and operational support at every step

Simply fill out the form.

One more step…

To complete the get in touch form or sign up, please click on the button below to enable cookies.