Catalase, Liquid

Terminox®

Terminox® is a family of bleach clean-up solutions available in a range of concentrations. Terminox® products contain a unique catalase that removes even the smallest traces of bleach. That leaves textiles ready for consistent, even batch-to-batch dyeing reproducibility.

Product features, details and benefits and image

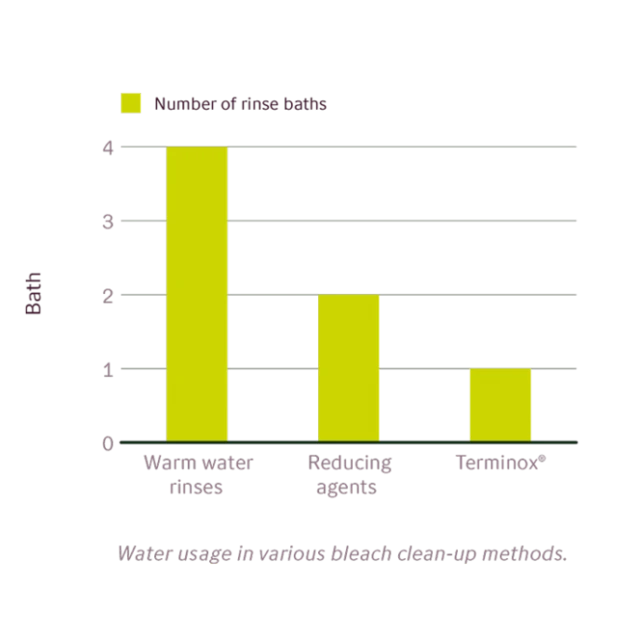

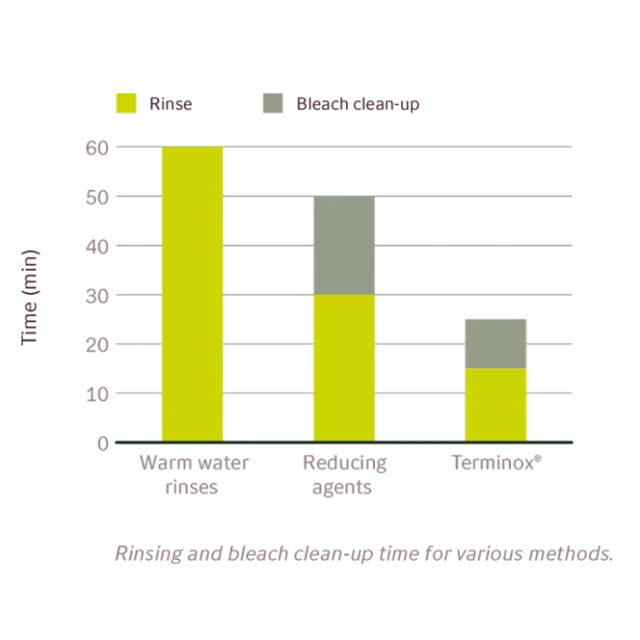

Traditional bleach clean-up processes with water or reducing agent use large amounts of water for rinsing. They also use lots of energy for heating and pumping the water. Depending on your process, Terminox® products could save you up to 30 minutes and between one and three water baths. That leads to energy savings.

Batch-to-batch reproducibility

Terminox® products prepare textiles for consistent dyeing results. That helps you avoid patches/uneven color. The result is final products with better overall color, as well as batch-to-batch reproducibility.

Flexible implementation

Enzymatic bleach clean-up with Terminox® products can be a stand-alone process. Using our patented CombiPolish® process, it can also take place together with biopolishing in the dye bath. Terminox® products are robust enough to work across a variety of temperature and pH ranges, so they can be implemented in most processes.

Higher production throughput

Terminox® products eliminate the need for further rinses before dyeing. That can allow you to more than halve your process time. With process times as low as 20-30 minutes, you can achieve higher production throughput.

Reduces effluent output or load

A conventional approach to bleach clean up is rinsing with vast amounts of water. Terminox® products ensure consistent bleach clean-up with far less water. The result is savings of 20,000 liters of water per ton of textile and reduced effluent output for your mill. Another approach to bleach clean up is reducing agents. These increase Total Dissolvable Solids (TDS) loads in your effluent. With Terminox® products, you can reduce these loads.

Safe dyeing

Cleaning up bleach with water alone leads to a risk of residual hydrogen peroxide affecting the color shade. With sodium thiosulphate, there's a risk of residual reducing agent affecting shade and evenness. This product helps your mill avoid these risks and achieve the desired shade and even dyeing.

A more sustainable solution

This product is both biodegradable and renewable. In many processes it saves water and energy. That makes it a more sustainable solution.

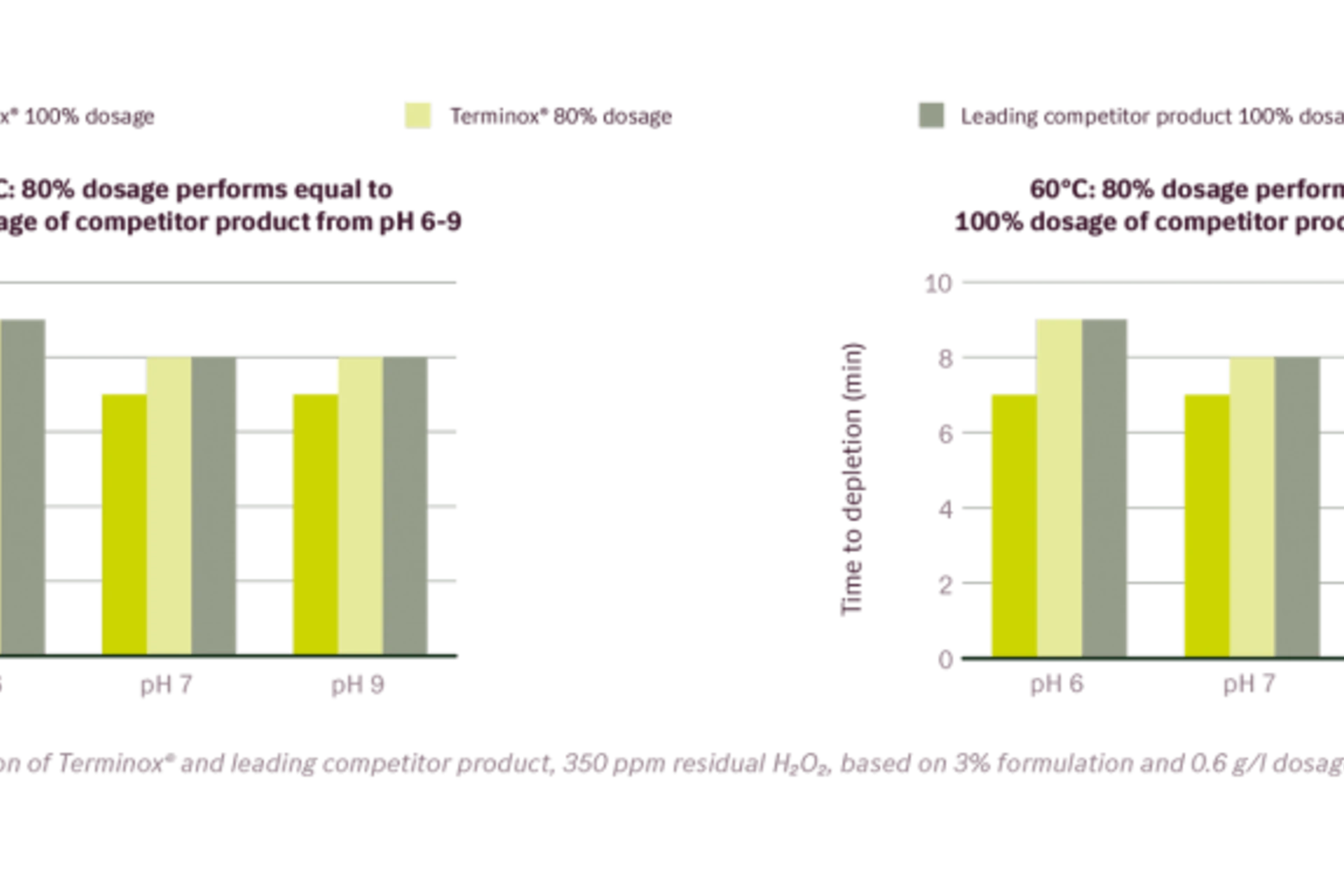

80% dosage, 100% performance with Terminox® products

Save between one and three rinse baths

Depending on your process, Terminox® products could save you between one and three water baths. That leads to water and energy savings.

Save up to 30 minutes

Depending on your process, Terminox® products could save you up to 30 minutes.

How catalases work in bleach clean-up

Residual bleach in fabric can prevent dyeing reproducibility. Catalases split hydrogen peroxide into water and oxygen. That makes them a fast, cost-effective alternative to water or reducing agents.

For consistent batch-to-batch dyeing reproducibility, each batch needs the same starting point. Textile mills achieve this by bleaching the fabric with hydrogen peroxide (H2O2) in advance. But any residual bleach will impact dyeing reproducibility. So it's just as important to 'clean up' all residual hydrogen peroxide in a bleach clean-up process.

Conventional methods of bleach clean-up include reducing agents or rinsing with vast amounts of water. Both methods can leave residual bleach or reducing agents such as sodium thiosulphate in the fabric. These will affect dyeing consistency.

Catalases simply split H2O2 into water (H2O) and oxygen (O2). That means there's no need for reducing agents or further rinses. Enzymes are also highly specific in their action, so any residual catalase won't affect the dyeing process or fabric.

Testing one of our products in your own production is the best way to experience all the benefits. Get in touch with us by filling out the form below.

One more step…

To complete the get in touch form or sign up, please click on the button below to enable cookies.