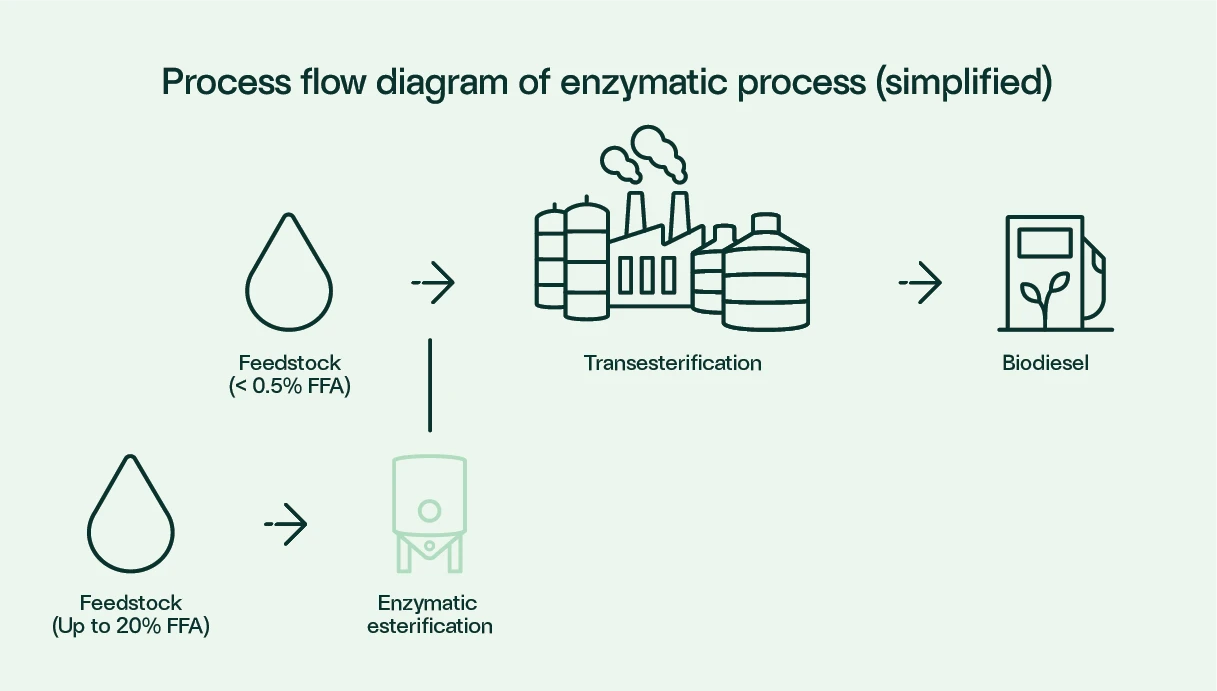

Like many biodiesel plant operators, you want to start processing waste feedstocks, such as used cooking oil and tallow, at the lowest possible cost. High free fatty acid (FFA) content in waste feedstocks leads to soap formation during biodiesel processing, resulting in significant feedstock waste.

Eversa® Advance complements your existing transesterification process and selectively converts up to 20% FFA to FAME with easy implementation and low CAPEX.

So waste-based feedstocks are not wasted. And neither is your profit.