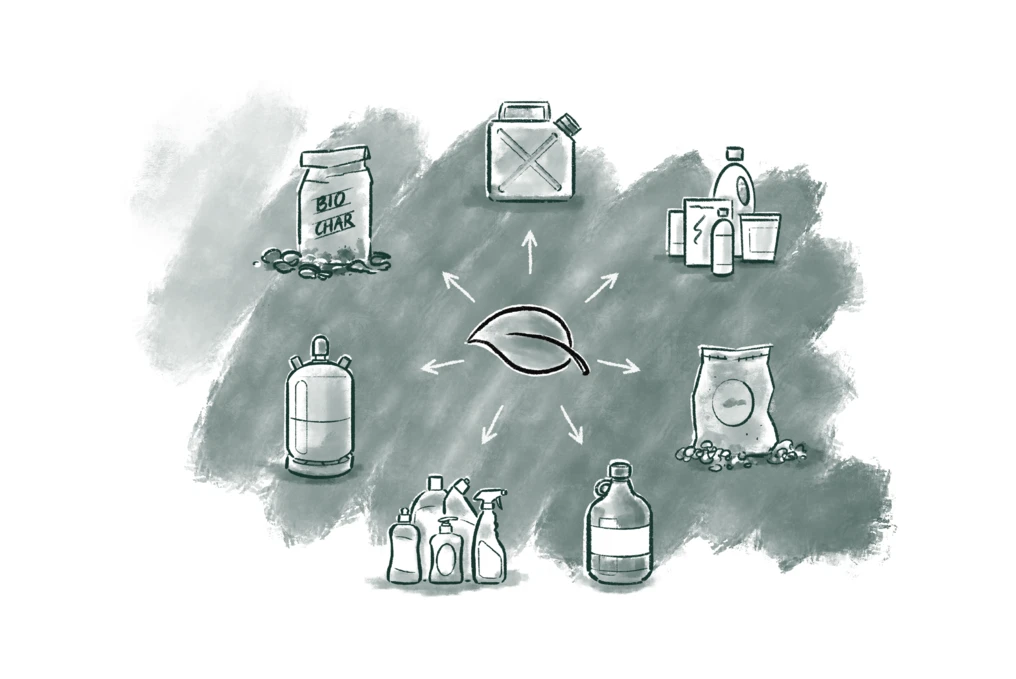

Biorefineries, turning every part of a plant into valuable resources

Biorefineries produce fuel, plastic, chemicals and char.

To understand the purpose and function of biorefineries, you must first learn something marvelous about the hunting practices followed by indigenous tribes. Due to their profound respect for nature, they utilize every part of a hunted animal's body – meat for food, hide for clothing and shelter, bones for tools, and even ligaments for binding materials.

This holistic approach not only honors the animal but ensures that nothing goes to waste as every part has some utility.

You can argue that biorefineries operate on a similar philosophy: breaking down plants into their various components and converting each one into valuable products.

The common practice across the world is we take whatever is the most easily usable part of a plant or a tree – fruits, timber, or seeds – and throw the rest away. For example, we harvest corn kernels and the cane from sugarcane but often waste the husks, leaves, and stalks.

What happens if we use all plant parts.

What happens to the unused parts of the plants? Most of it is condemned as waste or is incinerated. This wasteful usage of plants offers an opportunity for improvement.

For example, plants use a lot of resources to grow, including water, fertilizers, and soil nutrients. The more the whole plant is used, including what is often considered waste, the more value we get from each resource.

This is where biorefineries come into the picture. Here, plants are stripped down to their fundamental components and transformed into a range of valuable products, thus ensuring their maximum utilization.

But what are these components into which plants are stripped down and what are their uses? Think of plants and trees like buildings. Buildings are constructed from materials such as bricks, cement, wood, and metal, each serving a unique purpose. Similarly, plants are made up of different materials at the molecular level that give each part — stem, roots, leaves, shoots, trunk, and fruits — its specific texture and function. Let’s explore some of these important building blocks:

- Cellulose: Imagine the rigid, sturdy concrete beams of a house. Cellulose acts like these beams, providing structural support to the plant.

- Hemicellulose: Like how cement ensures all bricks in a wall are well-attached to each other, hemicellulose binds cellulose fibers together, providing strength and flexibility to plants.

- Lignin: Lignin is the substance that gives the wood in tree trunks their strength and durability. It provides rigidity and structural support, helping plants stay upright and resist decay.

- Starch: Picture starch as the plant's stored energy, similar to saving snacks for later. It’s what makes fruits sweet, cereals sticky, and potatoes dense. Starch acts as a reserve of energy that plants can use when needed.

So, what makes biorefineries so effective at breaking down plants and turning them into useful products? The key is enzymes and yeast.

Enzymes are natural, catalytic proteins found in all living organisms, from tiny microbes like bacteria and yeast to plants, animals, and humans. Biorefineries use enzymes from microbes to break down plants into their various components. Here are a few examples of enzymes used in biorefineries:

- Cellulases: These enzymes break down cellulose from plant fibers like stalks into sugar, which can then be fermented into ethanol, a cleaner fuel alternative to gasoline.

- Amylases: These enzymes convert starch from materials like corn kernels and sweet potatoes into sugar, which can be turned into ethanol.

- Proteases: These enzymes break down proteins in peptides and amino acids, which can increase the release of distiller’s corn oil, a feedstock for renewable diesel and SAF (Sustainable Aviation Fuel).

Once the enzymes have done their job, it’s the turn of yeast to show its magic by fermenting these broken-down plant components into useful products. This process also releases carbon dioxide gas, which can be further processed into valuable products through a process called Carbon Capture and Utilization (CCU).

Humans have shared a relationship with yeast for thousands of years. Yeast-driven fermentation has given us many solutions that have enriched our lives and it holds a key to securing our future, including against climate change. Curious to know more? Discover how yeast, fermentation, and their roles impact our lives here.

Another type of biorefinery is known as a wet mill. In a wet mill, corn is first steeped in a liquid to soften the kernels. The softened corn is ground and processed into separate components such as starch, gluten, and fiber. The extracted components can then be refined into a range of products, including human and animal-edible foods like high-fructose corn syrup, corn oil, and corn gluten meal. Wet mills allow for the efficient utilization of each part of the corn, maximizing its value and providing a diverse array of food and industrial products.

How can biorefineries help reduce oil dependence?

The biggest benefit of biorefineries is that they provide a way of utilising plants to produce a host of products, for which we have been reliant mainly on oil. These include:

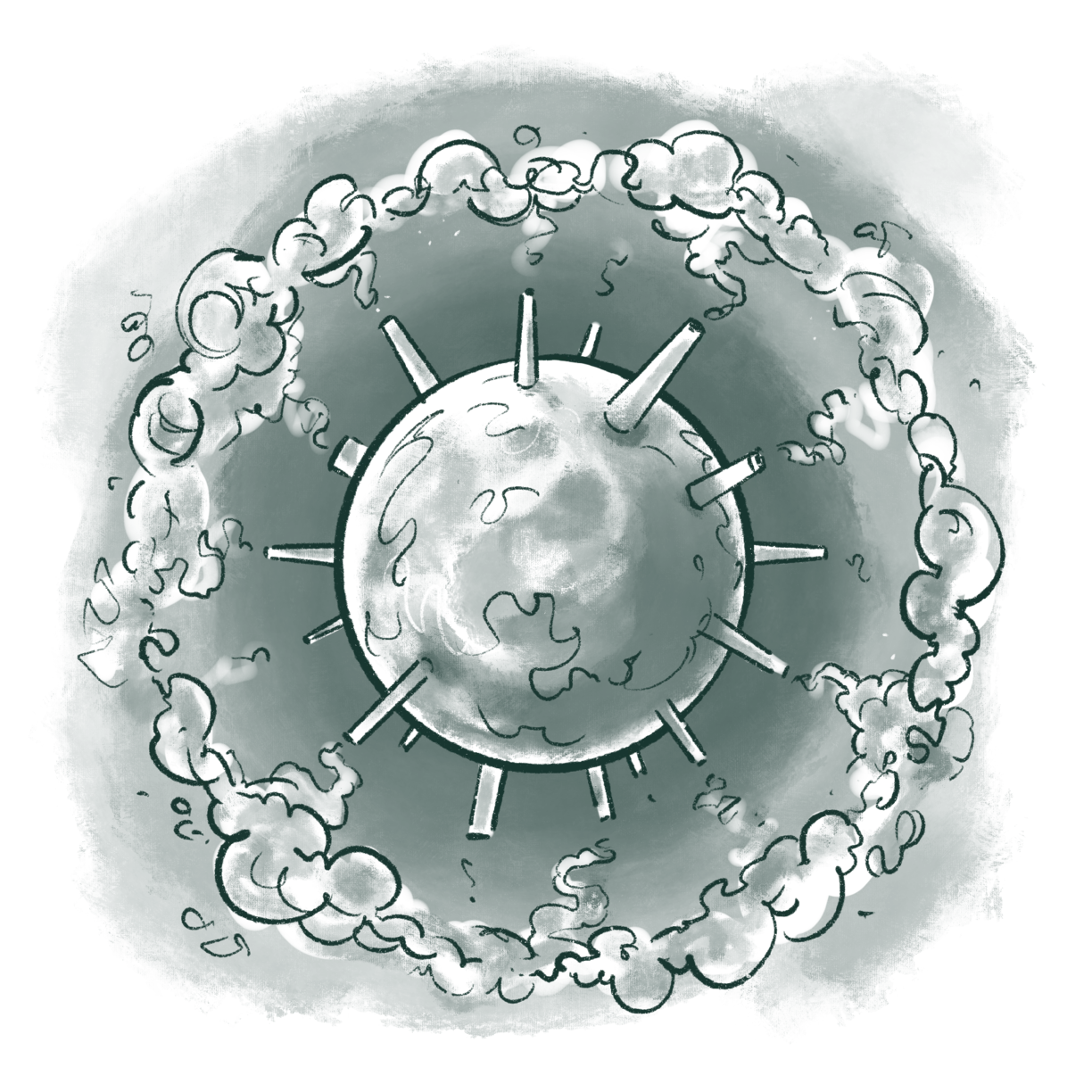

- Biofuels: Biorefineries are at the forefront of producing transportation fuels from plants and this goes a long way, as biofuels emit between 19% - 86% less greenhouse gases than petrol14. The biofuels derived from plants in biorefineries include:

- Ethanol: Derived from crops like corn and sugarcane, ethanol is commonly blended with gasoline to reduce emissions and dependence on fossil fuels.

- Biodiesel: Produced from vegetable oils, municipal sludge, and algae, biodiesel can be used in diesel engines, offering a cleaner alternative to petroleum diesel.

- Sustainable Aviation Fuels: Ethanol produced in biorefineries or waste cooking oil can be further processed into SAF.

- Bioplastics: Plastics are essential in modern life, but most are made from oil. Biorefineries can help create plastics from renewable resources like Polylactic Acid (PLA), which is made from fermented plant sugars. PLA is used in items like packaging and disposable cutlery, providing a biodegradable alternative to conventional plastics.

- Bio-based chemicals: Many chemicals are derived from oil, but biorefineries can produce these from plant-based sources. One such chemical is succinic acid, a versatile chemical, found in household cleaning products, pharmaceuticals, and food additives.

- Biochar and agricultural Inputs: Biorefineries also produce biochar from plant residues and organic waste. Biochar, a form of charcoal if you will, enhances soil fertility and reduces the need for synthetic fertilizers, which are often petroleum-based.

- Biogas: Biogas produced from plants with the help of enzymes and microbes can be used for heating or electricity, offering an alternative to natural gas.

- Animal feed: Dried distillers’ grains with solubles (DDGs) are a byproduct from ethanol production, and can be used as high-quality feed for livestock.

Embracing plants and enzymes for a greener future

Crude oil has undeniably shaped human civilization, driving progress and innovation. However, its environmental toll and contribution to climate change have become impossible to ignore. The call for cleaner, greener alternatives has led us to the groundbreaking realm of biorefineries. By harnessing the transformative power of enzymes, we can transform plants and other organic waste into biofuels, bioplastics, and bio-based chemicals. This shift from crude to cultivated is not merely a necessity but an opportunity to improve our relationship with the planet.