Oleochemicals

Optimize your oleochemical production for lower costs

Producing oleochemicals with enzymes improves both your operation and the quality of your products

Sustainable solutions for fatty acid and ester production

As a key component in everything from personal care products and pharmaceuticals to food additives and industrial applications, oleochemicals offer a sustainable alternative to petrochemical-based products.

Our solutions for fatty acid and ester production help make your operation more profitable.

And with support from our technical team, they are also easy to implement in your plant.

Pre-splitting for fatty acid producers

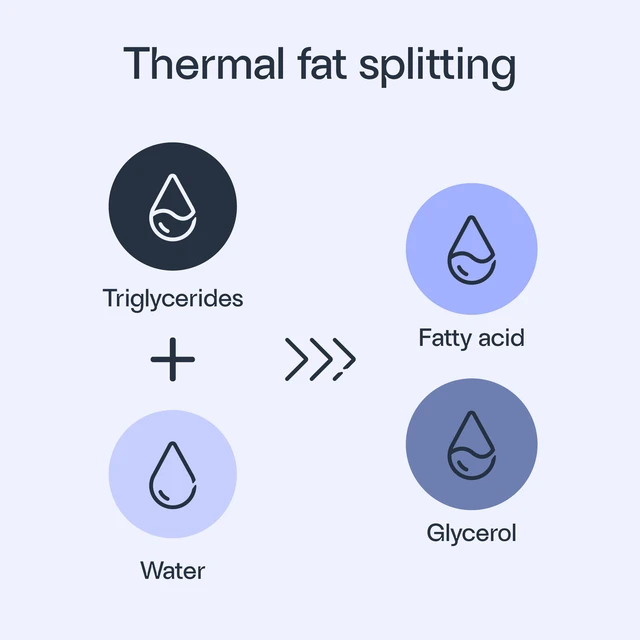

Fatty acid is an integral element in a variety of products, from lubricants to foods. The most common way to convert fats and vegetable oils in feedstocks into fatty acids and glycerol is through thermal fat splitting. With enzymatic pre-splitting, you can boost the efficiency of thermal splitting, resulting in up to 30% energy savings, and a higher degree of splitting-- all with little or no CAPEX costs.

Significant energy savings and higher ester quality

Together with thyssenkrupp Uhde (one of the world’s leading full-service providers for chemical plants), we are proud to offer a new enzymatic esterification process that allows producers to replace chemical catalysts, save energy and reduce greenhouse gas emissions by up to 60%.

The short reaction time and low operating temperature results in lesser waste and better product quality.

Our solutions for oleochemicals

- Higher ester yield

- Lower operational cost

- Higher quality esters

- More sustainable

- Increased energy savings

- Higher degree of splitting

- Higher throughput

- Increased water savings

What could this mean for your business?

Fill in the form below and we’ll be in touch.

One more step…

To complete the get in touch form or sign up, please click on the button below to enable cookies.