Safe handling

Baking Mix

Achieving consistent, high-quality baked goods starts with safe, effective handling of your baking mixes. Whether you're producing bread, cakes, or pastries, ensuring a smooth and hygienic process is key to minimizing risks and maximizing productivity.

Baking Safety

Safe handling of enzymes

Get our product safety expertise

Dosing of enzymes

How to ensure the right dosing

Recipes & results

Use the baking mix with your favorite bread recipe – or try ours

Products in the baking mix

See below our portfolio of baking products

Get our product safety expertise

Novonesis’ extensive experience of producing enzymes has given us a high level of expertise in handling them, as well as microorganisms. We feel very strongly about our responsibility to share this product safety expertise with our customers.

Enzymes are safe to use in consumer products. However, they may cause allergies for people working with enzymes in industrial processes if not handled correctly. Our safety videos help guide operators, supervisors and other professionals on how to ensure a safe working environment. You can also read more in our safety guidelines.

How to ensure the right dosing?

Application:

Add 1 teaspoon of Baking Mix (5 g) to 500 g wheat flour

Add 1 bag of Baking Mix (20 g) to 2 kg of wheat flour

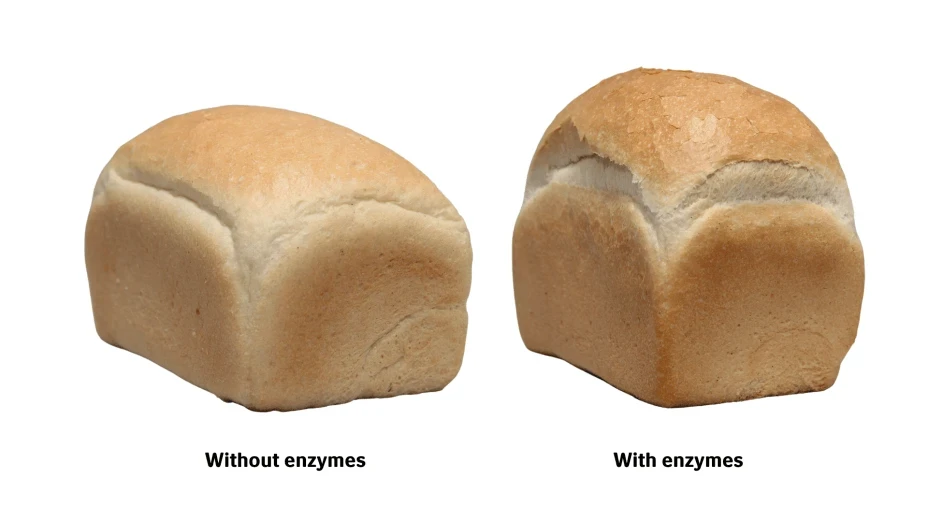

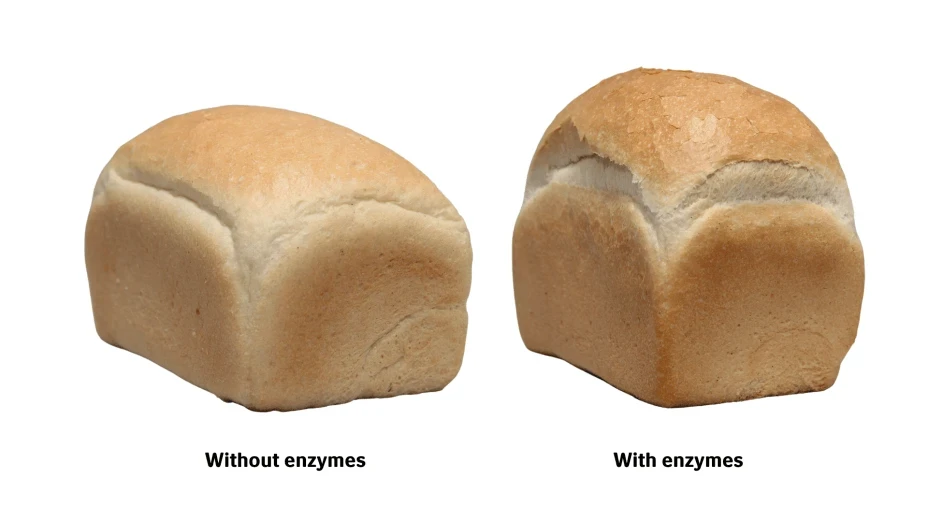

Recipes & Results: White Pan Bread

Recipe and procedure

| Recipe | Baker's (%) | For 2kg flour (gr) | For 500 gr flour (gr) |

|---|---|---|---|

| Water | 58 | 1160 | 290 |

| Flour | 100 | 2000 | 500 |

| Yeast | 3.5 | 70 | 17.5 |

| Salt | 2 | 40 | 10 |

| Sugar | 1 | 20 | 5 |

| Baking Mix | 1 | 20 (1 bag) | 5 (1 teaspoon) |

| Ascorbic-acid (60ppm) | 0.006 | 0.12 | 0.03 |

| Procedure | Minutes |

|---|---|

| Spiral Mixer slow | 2 |

| Spiral Mixer fast | 10 |

| Evaluation | 5 |

| Scaling bread (330gr) rounding | 5 |

| Bench time (covered) | 10 |

| Moulding/panning | 10 |

| Proofing: 36 C; 90 rH | 60 |

| Baking: 220 C (with steam) | 30 |

Recipes & Results: White Spelt Bread

Recipe and procedure

| Recipe | Baker's (%) | For 2kg flour (gr) | For 500 gr flour (gr) |

|---|---|---|---|

| Water | 58 | 1100 | 275 |

| Spelt flour | 100 | 2000 | 500 |

| Spelt gluten | 1.5 | 30 | 7.5 |

| Yeast | 3 | 60 | 15 |

| Salt | 1.8 | 36 | 9 |

| Sugar | 1 | 20 | 5 |

| Baking Mix | 1 | 20 (1 bag) | 5 (1 teaspoon) |

| Ascorbic-acid (60ppm) | 0.006 | 0.12 | 0.03 |

| Procedure | Minutes |

|---|---|

| Spiral Mixer slow | 8 |

| Dough table time | 60 |

| Scaling/rounding | 10 |

| Bech time (covered) | 10 |

| Moulding | 10 |

| Proofing: 36 C; 90 rH | 35 |

| Baking: 250/220 C (with steam) | 30 |

Products in the baking mix

- Improved oven spring and higher loaf volume

- Less off-flavor in buttery recipes

- Uniform crumb structure

- Less dependence on emulsifiers

- Improved crust color

- Improved volume and crumb structure

- Suitable for organic products

- Intensified surface collaration

- Improves texture & appearance

- Enhanced fermentation

- Improves texture immediately after baking

- Delivers fresher than fresh

- Enables fresh keeping

- Allows recipe optimization

- Reduces food waste and returns

- Reduce dependence on emulsifiers

- Improved product volume, crumb structure and appearance

- Good dough machinability and handling

- Improved dough extensibility

- Optimizes cost & process