Turning a ban into a boon

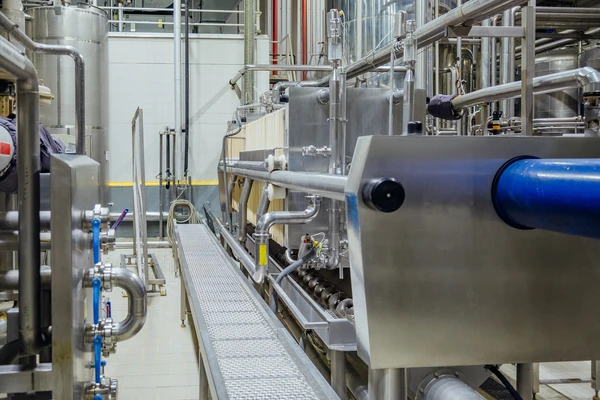

Case study: See how this brewer maintained production efficiency and beer quality despite barley import restrictions.

Production efficiency down due to raw materials

Brewers experienced big variations in the quality of raw materials when imports of barley were banned in their country. It affected both production efficiency and quality of finished beer products of a regional brewer.

Ceremix® Pro improves filtration and beer quality

By using Novonesis’ brewing solutions such as Ceremix® Pro, the brewer was able to cope with these fluctuations in raw material quality and optimize its filtration process. Total production efficiency and final beer quality also improved.

Location: Asia-Pacific

Explore more success stories.

Overcoming raw material quality variation

Challenge: A country-wide ban on barley imports led to significant variation in raw material quality – which dropped production efficiency and the quality of finished beer products. Challenge: A country-wide ban on barley imports led to significant variation in raw material quality – which dropped production efficiency and the quality of finished beer products.

Troubleshooting a lautering problem

Challenge: Something was making a regional brewer’s lautering process take much longer. And the brewer couldn’t produce the amount of beer required due to the longer brewing cycle time.

Enzymes help overcome equipment limitation

An international brewer wanted to implement a known recipe into another of its breweries. But the “new” brewery did not have a cereal cooker. How to overcome the equipment limitation?