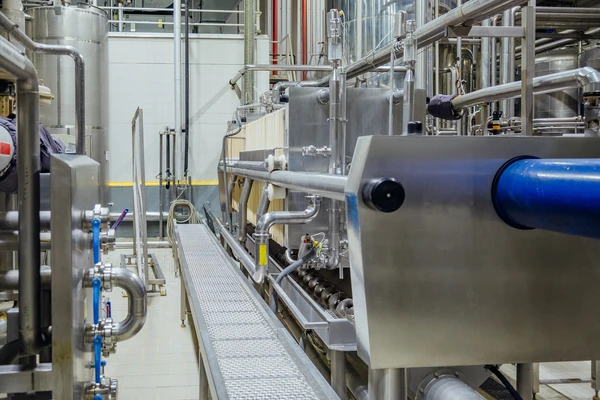

Optimize wort separation and beer filtration

To optimize your brewing capacity, you need fast and efficient wort separation and beer filtration. Enzymes can help - without compromising quality.

The problem with β-glucan and arabinoxylan

The efficiency of separating the wort from the mash depends on the large molecules dissolved in the liquid.

Various cereal grains have molecules with high molecular weight, but in different amounts and ratios. For example barley, oats and sorghum have more than twice as much β-glucan as xylans. But wheat and rye have the opposite.

β-glucans and arabinoxylans create high wort viscosity, which dramatically slows mash filtration. They stick to filter aids and membranes. They also stick to starch molecules, making them less available for enzymatic degradation. This can reduce yields and cause haze.

Maximize your capacity, minimize investment

The Novonesis range of filtration enzymes supports consistent, fast and efficient wort separation and beer filtration. This allows you to maximize your number of brews per day and optimize yields and filtration cycles.

Our enzymes work effectively at a wide range of mashing temperatures, making it easier to produce high-gravity beers and to achieve a higher extract yield.

At the same time, they help you keep your investment in brewhouse and beer filtration capacity as low as possible.

Case studies

From launching new beers to optimizing existing recipes and more, our customers have leveraged our solutions to stay ahead. Check out these success stories to explore how they've used our innovations to overcome challenges.

Predictable, stable filtration

For years, an international brewer had used the same product for hemicellulose breakdown in its recipes, which go from 10-40% barley. But the brewer faced variable filtration performance in the brewhouse and downstream (beer filtration) as well as extract yield variability.

Troubleshooting a process-bottleneck

A regional brewer was facing extended lautering times, which were delaying production and preventing them from meeting beer output requirements. Novonesis was tasked with identifying the cause of the bottleneck and recommending possible solutions.

Filtration benefits far exceed enzyme cost

For years, this regional brewery had used a “traditional” beta-glucanase in its process. It was now looking for a better wort and beer filtration process.

With our solution, it was able to speed up its filtration process by 30%, and at the same time reduce its use of filtration aids by 40%.

Better yield, productivity and performance

The “traditional” beta-glucanase a regional brewer was using was limiting the efficiency of its wort and beer filtration process. Because beta-glucans and arabinoxylans create high wort viscosity, they dramatically reduce mash filtration speed – sticking to filter aids and filter membranes.

Explore our solutions

- Faster wort separation

- Increased brewhouse capacity

- Faster beer filtration

- Haze reduction in final beer

- Increase extract yield

- Thermostability

- Consistent performance for undermodified malt

- Enhance sustainability claims

- Thermostability

- Avoid the formation of fermentable sugar for low alcohol beer

- Faster wort separation

- Increased brewhouse capacity

- Faster beer filtration

- Haze reduction in final beer

- Increase extract yield

- Faster wort separation

- Increased brewhouse capacity

- Increase extract yield

Other beer applications

Get in touch.

Have questions? We’d like to hear more about what you need.

One more step…

To complete the get in touch form or sign up, please click on the button below to enable cookies.